Manufacturing systems generate a massive amount of data. This data is generally very difficult to mine given the scale and non-homogeneity in the data sources. However, mining this dark data could yield significant returns. With increasing automation, shop-floor analytics will become extremely critical for efficient operation.

Sumit Guha, head of analytics at Asian Paints took us through the adoption of artificial intelligence on shop-floor and various approaches towards harnessing system-level manufacturing data to transform operations on the shop floor, at plugin 2020

Manufacturers currently use AI and machine learning to solve specific problems in production, helping operators uptime, optimise production and more. Some of the areas that he covered included the importance of a unified data model, driving change management, results from implementation and key learnings.

Shop-Floor Analytics

While applying analytics in manufacturing has not been the main scenario until now, AI and ML are now being implemented to not only reduce unexpected downtime but also achieve better yields and improved quality. Talking about Asian Paints which is the largest paint manufacturer in India and ninth in the world with consumers in more than 65 countries, using analytics becomes crucial. As the company is also expanding in various avenues such as paint tools, adhesives, wall coverings, decor and now sanitizers, the importance of shop floor analytics is more than ever before.

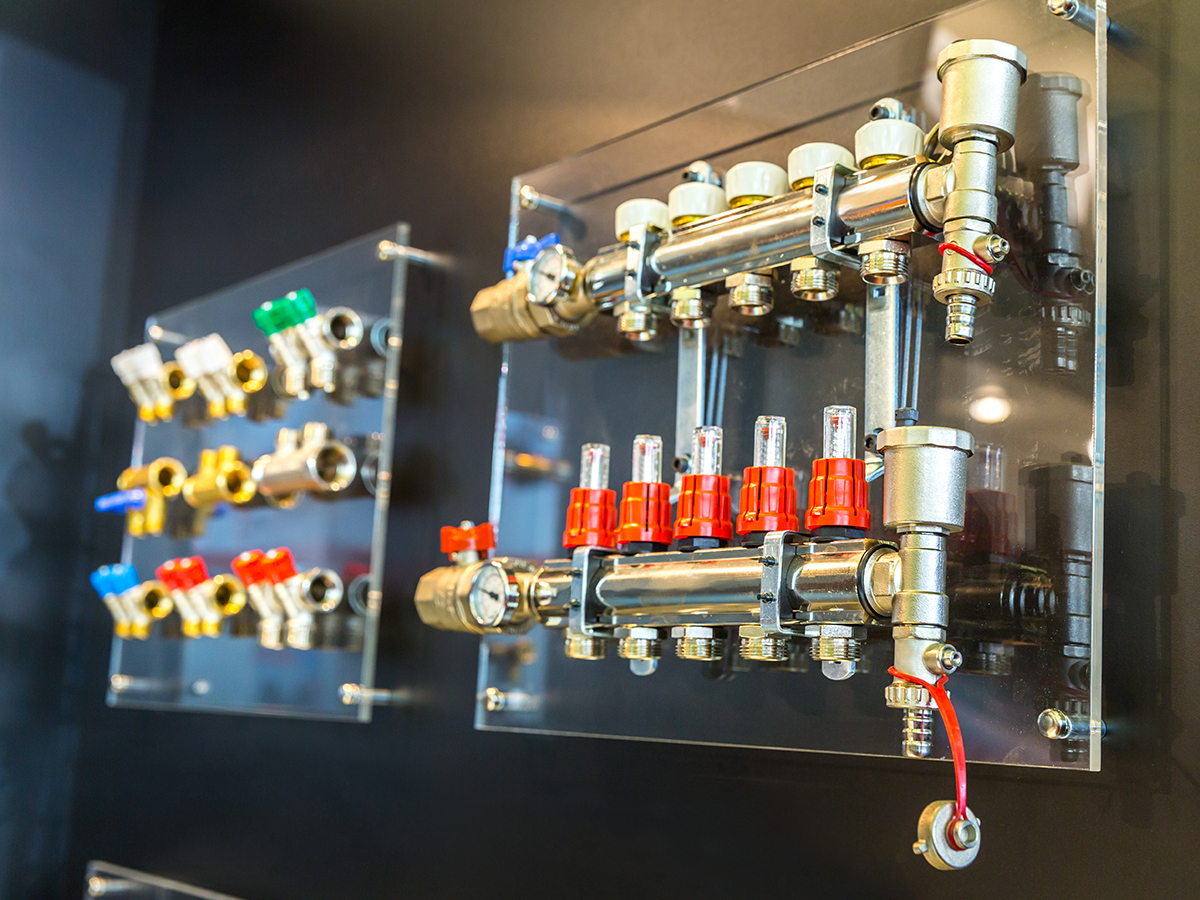

Guha shares that adding new capabilities in a factory is a huge cost with machines and various functionalities that are needed to be put in place. It is also true that these machines emit a lot of data being connected to different sources and are a gold mine of data. These data are mostly unused and may not benefit the company as it should. There are 400+machines and multiple lines with a lot of people at the core of a manufacturing company. Therefore, having the right systems in place is important. Analytics, therefore, plays an important role in making sense of it.

Explaining the step-by-step manufacturing analytics, he shared how descriptive, diagnostic, predictive and prescriptive data makes ways through various channels, ultimately yielding insights into outcome-based products that Asian Paints has adopted.

Creating Data Models

They also built a conceptual framework addressing issues such as which equipment is like to fail in the next 30 days, what adjustments should be made to the batch to get right RFT, what are the current bottlenecks and more. The technology that was used included edge processing, among others.

Guha shares that creating models is the most crucial step and is at the core, as when these data models are implemented correctly, it may yield a lot of important results such as revenues. Building any application may need to develop the user interface, application servers, data storage, data processing, data movement, protocol converters, edge devices and more. “For any application to build, you have to build things step-by-step so that the desired results are achieved,” he said.

People & Process Is Also Important

Apart from having the right technology in place, Guha shares that it is important to have people and processes in place. It is important to seek right sponsorship, a right structure such as technology and data science to sustain the initiative, and more. The company also conducted hackathons to accomplish tasks such as accuracy, asset optimisation, predicting scenarios such as batch mixes, recommending batch mixture and more. Guha suggested that the company had been able to accomplish 7-17% work accuracy.

Key Learnings

- An analytics journey is more of a cultural change

- Spend time in building business case upfront and visualise how insights will be put to use

- Start small but do not take shortcuts

- Work with partners to get expertise

- Identify the right project sponsor

- Have the right operational teams with the right insight

- Domain knowledge is important

- Get your leadership inspired, educated and excited