|

Listen to this story

|

The semiconductor space has hitherto been a vast, unexplored territory for India. However, the government now wants to place the country firmly on the global semiconductor manufacturing map. Speaking at the Semiconductor Conference 2022, India, Prime Minister Narendra Modi said that his government is cognizant of the untapped potential in the sector.

“We are committed towards the acceleration and growth of the chip design and manufacturing ecosystem in the country. An ecosystem that is built on the principle of ‘hi-tech, high quality and high reliability’, Modi said.

With the right policies in place, incentives for manufacturers, and support from the industry, the Prime Minister believes India could become a global semiconductor manufacturing hub.

While the government seems to be on the right track, does India have the capabilities – the right policies, the technology, the workforce and the right ecosystem to establish itself as a global semiconductor powerhouse?

A timely move

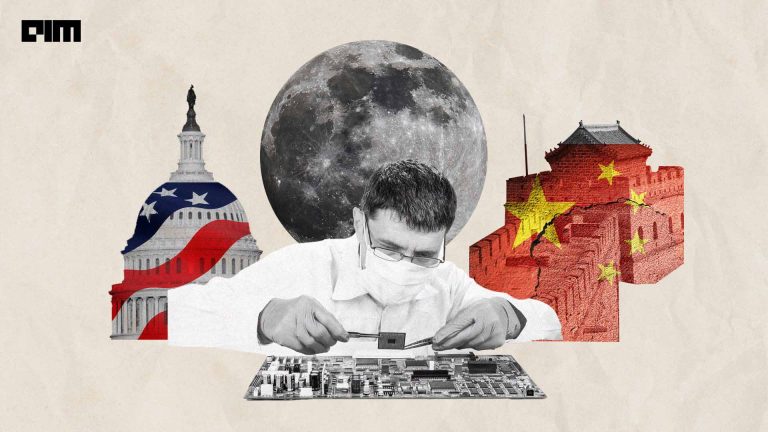

India’s push to establish a semiconductor hub in the country has come at a time when major chip manufacturers are looking to decouple their supply chains from China. India is poised to benefit from the growing trade and geopolitical tension as China continues to fight the virus with stringent lockdown measures.

Vedanta and Foxconn‘s announcement this week to establish a fabrication and semiconductor manufacturing facility in Gujarat gave India’s ambitions a significant boost. Vedanta will invest around INR 1.54 lakh crore to set up the unit.

Last year, the international semiconductor consortium ISMC announced that it would invest USD 3 billion to set up India’s first and largest semiconductor fab in Karnataka. ISMC signed an agreement with the state government. The unit will be set up in partnership with the Intel-owned Tower semiconductors.

India’s aspiration to become a global semiconductor manufacturing hub is not new. Back in 2005, the country tried to attract semiconductor manufacturing giants to set foot in India; however, unfavourable business conditions and bureaucratic hurdles drove them away.

India’s attempts to lure chipmakers in 2017 and 2020 didn’t bear fruit either. However, things are finally looking up. Today, every country is trying to establish a semiconductor manufacturing base, with countries like Singapore, Malaysia, Japan and even Vietnam joining the race. In addition, countries with established manufacturing hubs like China, South Korea, and Taiwan are trying to grow further in terms of semiconductor manufacturing capability.

“While several of these countries, such as the US or Taiwan, have a strong prior experience, Indian advantage is its vast, bustling market, which many of the other countries, embarking on semiconductors, do not. Besides, India has significant local demand justifying the volumes required to drive this kind of initiative and a great workforce pool required to drive such an initiative, which many other countries don’t have. So in that sense, India is better placed compared to many of these countries,” Prof. Mayank Shrivastava of the Indian Institute of Science (IISc), stated.

This MoU is an important step accelerating India’s semi-conductor manufacturing ambitions. The investment of Rs 1.54 lakh crore will create a significant impact to boost economy and jobs. This will also create a huge ecosystem for ancillary industries and help our MSMEs. https://t.co/nrRbfKoetd

— Narendra Modi (@narendramodi) September 13, 2022

Chip cold war

Today, over 60% of the foundry market is dominated by Taiwan. It almost has a monopolistic hold regarding the advanced technology nodes, which are used in many electronic devices and even military tech. The ability to produce these chips locally will allow India to circumvent a chip cold war.

Explaining further, Prof. Shrivastava said, “Imagine if all advanced strategic (space, defense, and what can affect human lives) technologies are dependent on these chips, and if the countries supplying chips to us suddenly stopped exports to India, what would we do?”

For example, the US government recently banned certain advanced chips manufactured by Intel and a couple of similar companies in the US from being shipped to China. “In such a scenario, China will have to either manufacture those chips or would have to agree to certain terms and conditions from the US. Luckily for China, they are in a better position. They already have a good hold in chip manufacturing, chip design, etc. We, however, are not there yet.”

Hence, manufacturing these advanced chips will not only make India self-reliant but will also keep us in the driving seat. “Access to advanced technologies will always be the deciding factor in determining which country will lead in the future. Therefore, to become a leader or a global power, we must become the leader in advanced technologies and the basic building blocks of what drives all these technologies, i.e., chip manufacturing ability.” Prof. Shrivastava added.

Government policies and subsidies

Last year, the government of India announced a production-linked incentive (PLI) scheme called Semicon India for semiconductor and display board production to attract chip manufacturers to set up camp in the country.

Through this programme, the government plans to spend around INR 76,000 crore in semiconductor production over the next 5-6 years. The government is looking to provide financial assistance to companies that invest in semiconductors, display production, and the design environment.

Prof. Shrivastava also believes that the government is on the right track. “We are in a fortunate time that we have the right people in place driving the process. They understand the international ecosystem and interdependencies, whether it is the raw material supply chain, supply and demand, return on investment, and the time needed to get to a point to fill your complete production capabilities with the local demand,” he said.

India’s semiconductor mission

Today, almost all advanced gadgets available in the market, from consumer electronics to defence electronics – everything requires semiconductor chips in some form. However, India’s semiconductor demand is met entirely through imports.

Through the semiconductor mission, the government wants to establish a reliable semiconductor supply chain, including raw materials, specialty chemicals, gases, and production equipment.

The objective of the mission is to formulate a long-term strategy for developing sustainable semiconductors and a semiconductor design ecosystem in the country.

Challenges ahead

While speaking at the SemiconIndia Conference 2022, Modi said that India is uniquely positioned to be an influential player in the segment owing to its consumer base and skilled engineering workforce.

Prof. Shrivastava, too, believes we have the right ecosystem in place. “We have everything needed to establish India as a global semiconductor manufacturing hub. The only thing we don’t have is prior manufacturing experience in semiconductors, where global players come into the picture in collaboration with local investors such as Vedanta. This gap can be easily bridged using the know-how and expertise available in the country.”

However, the decision to establish a semiconductor fab in the country ultimately lies with the company investing in Fab and offering the technology. “This is the toughest part of the game; therefore, the companies are always conscientious. India needs to ensure that the worries, concerns or gaps these companies see are addressed at the earliest lest we lose these companies to other countries,” Prof. Shrivastava further added.

Whether it is land, water, power, supply chain ecosystem, or raw material, if the government can address all these challenges, there is no reason for companies not to set shop in the country.

Further, having a manufacturing plant alone is not enough for India to become a leader in this space. India must invest heavily in intellectual property creation and R&D in future technology generations to be future-ready, which is essential to embark on becoming a global leader.

“These chip technologies are heavily driven by intellectual properties (IP). If India is investing in chip manufacturing facilities or chip manufacturing, India also needs to invest in IP production for future technology solutions. These future technology solutions could be quantum technology or something that could prove to be a substitute for silicon like 2D technologies. India needs to start investing in some of these future technology nodes right at this stage. So when these future technologies come into play, India will have the advantage compared to the rest of the world,” Prof. Shrivastava concluded.