|

Listen to this story

|

The revisions made to India’s existing semiconductor policy have made it ripe for investors to build a semiconductor ecosystem within India, but only a few players have chosen to avail of the scheme.

Analytics India Magazine spoke to Sravan Kundojjala, director at Strategy Analytics, to understand why companies who have the capital to invest, even with the incentives provided, are hesitant to take the long stride into semiconductor manufacturing in India.

Kundojjala attributed this to a variety of factors. First and foremost, setting up a semiconductor plant requires huge capital expenditure, while the profitability is very low, at least during the initial period. This, he believes, is due to the fact that “it takes time for companies to get to the break-even point, and ramp up the number of wafer starts per month.”

Naveed Sherwani, chairman, president & CEO at RapidSilicon, explained two things about setting up a fab—one, once a fab is started it can never be stopped, and second, it needs 80-85% capacity to make any money.

Strong global competition

Additionally, the demand is very cyclical in the industry. And to survive, the financials have to be very strong, especially when there is ample global competition looming around. Companies like Semiconductor Manufacturing International Corporation (SMIC), GlobalFoundries, and United Microelectronics Corporation (UMC) are pushing for expansion in countries like France, US, Singapore, Taiwan, and Japan— further stifling the market share that India can obtain if at all it gets its feet up and running by 2025, or 2026. UMC and Taiwan Semiconductor Manufacturing Company (TSMC), for instance, are deploying resources for the production of 28nm chips in Singapore and China, respectively, whereas GlobalFoundries are investing in Europe in the 22FDX range.

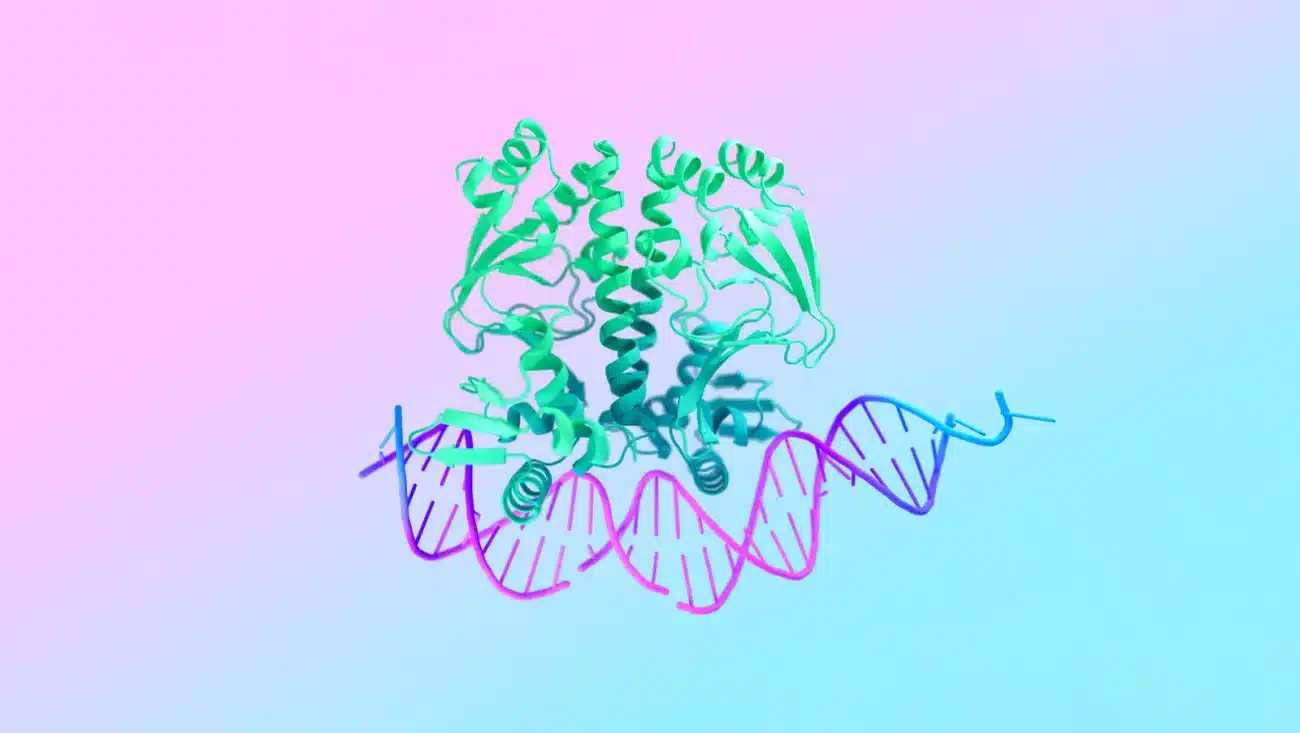

The 28nm range has been a hot item in the semiconductor manufacturing space. It is used for a wide set of applications, including WiFi chips, Bluetooth chips, camera image sensor, display driver ICs, or management chips, RF transceivers, and sensors like fingerprint sensors, MEMS, etc, and has also been the target of applicants availing the government scheme on semiconductor manufacturing in India.

However, the concern, as Kundojjala admitted, is will India be able to build a solid base, and get the factories running fully loaded, in the initial stage, when there is heavy competition? Arun Mampazhy, a veteran semiconductor analyst, in addressing what the foreign expansion in 28nm range means for India, said this:

Earlier UMC said 28nm may have over capacity after 2023. If T$MC also switches to "two 28nm fabs" plan at Kaohsiung instead of "7nm + 28nm", it is bad news for India's 28nm plans. IMO, 65nm Analog remains a safer bet even if "experts" advise @GoI_MeitY @AshwiniVaishnaw otherwise. https://t.co/lZwZHPBdjl

— arun mampazhy (@nano_arun) November 14, 2022

However, the government can make certain policy interventions to give the semiconductor manufacturers an edge in the Indian market. “As of now, as long as companies in India register in CHIMS (Chips Import Monitoring System), the import of chips won’t have a custom duty. But later, the government can levy customs duty on the import of those chips whose requirements can be filled by fabs in India,” Mapazhy told AIM.

Robust government backing needed

In the semiconductor industry, the government is the backbone, incentivising a lot of investments and getting the supply chain in order. A country like India in particular, which is yet to walk through the semiconductor waters (with its ebb and flow), needs strong government backing to get the process running at least during the initial stretch, when companies lose a lot of money. In this regard, Kundojjala said, “We shouldn’t look at this [India’s] investment as consisting of one or two years, it should be there at least for 10-15 years to have things play in favour of you.”

He also cites the example of the Taiwan government which offered a lot of incentives to TSMC and EMC when they initially started, providing infrastructure and human resource support. These companies, for instance, sent their engineers to the US for training, who later came back to set up these foundries.

When asked about what should be the state of subsidies going forward, Kundojjala said that the allowance should ideally be raised if we are looking to get more into more cutting-edge technology with a 28nm process. However, for the 45nm, 55nm process, which is considered to be the sweet spot currently, and will be so at least until 2030, considering the number of applications in areas of power electronics, and periphery modules inside numerous consumer applications that we use currently, the present allowance should work fine, provided the government is ready to taken the burden of loss during the beginning phase.

Texas Instruments is a big name targeting between 45nm and 130nm nodes, spending about $24 billion on four fabs, each with a capex of about $6 billion.

But, what if the nodes that are currently above 28nm migrate to the advanced category—that is, with the growing pace of technology, how is it guaranteed that technologies that currently need chips of 28nm and above would not move to 16nm nodes tomorrow?

In response to this, Kundojjala said that in analog chips, you cannot scale well beyond a certain node. At this stage, even increasing the transistor density will not impact components such as performance, power consumption, savings, etc. This further attests to the fact that for at least a decade, there would be a market for mature nodes which India can utilise and sow the seeds for future investments for production of advanced chips used in defence, AI, and other developing technology.

Reality check

Semiconductor consumption in India is expected to grow to roughly $70 billion by 2026, said India Electronics and Semiconductor Association (IESA) chairman, Vivek Tyagi. In this light, the Government of India’s semiconductor mission is aligned with building a robust semiconductor supply chain to enable India’s emergence as a global hub for electronics manufacturing and design.

But, in reality, there is still no sense of urgency seen on ground in the government’s actions. Union Minister Ashwini Vaishnaw, earlier in April, said that the approval for making electronic chips will likely be done in the next 6 to 8 months.

However, at a recent Bengaluru Tech Summit. Karnataka’s IT Minister CN Ashwath Narayan clarified that the central government would decide on which company would build a semiconductor plant, and which state would house it by February 2023. The statement brought disappointment to many who were anticipating the government to take swift actions on the proposals received. A Twitter user by the name ‘EkNashwar’ expressed frustration with the present state of affairs saying this:

It's a pathetic bureaucratic show of delay from @GoI_MeitY @AshwiniVaishnaw @Rajeev_GoI where just approval will take 12+ months, just when semiconductor glut is being predicted. During the same period, US approved and funded $280 billion over 10yrs, so did EU, SoKo & Japan.

— एक नश्वर (@EkNashwar) November 8, 2022

India’s major advantage, as Kundojjala reiterates, is that it is politically neutral in the global scheme of things. At a time when China is cut off from advanced AI equipment and AI processors due to the geopolitical battle it is engaged in, building a strong base to strengthen the ecosystem becomes paramount. Japan is already doing this. According to reports, eight major Japanese tech firms, including Sony and Toyota, have teamed up to form a consortium by the name Rapidus, aimed towards mass-producing advanced 2nm chips by 2027. The Japanese government has vowed 70 billion yen (~$500 million) to back Rapidus.

It is time the Indian government recognises this and takes prompt steps to make India a strong nodal point for global semiconductor supply—and for this, mature node is just the start.