|

Listen to this story

|

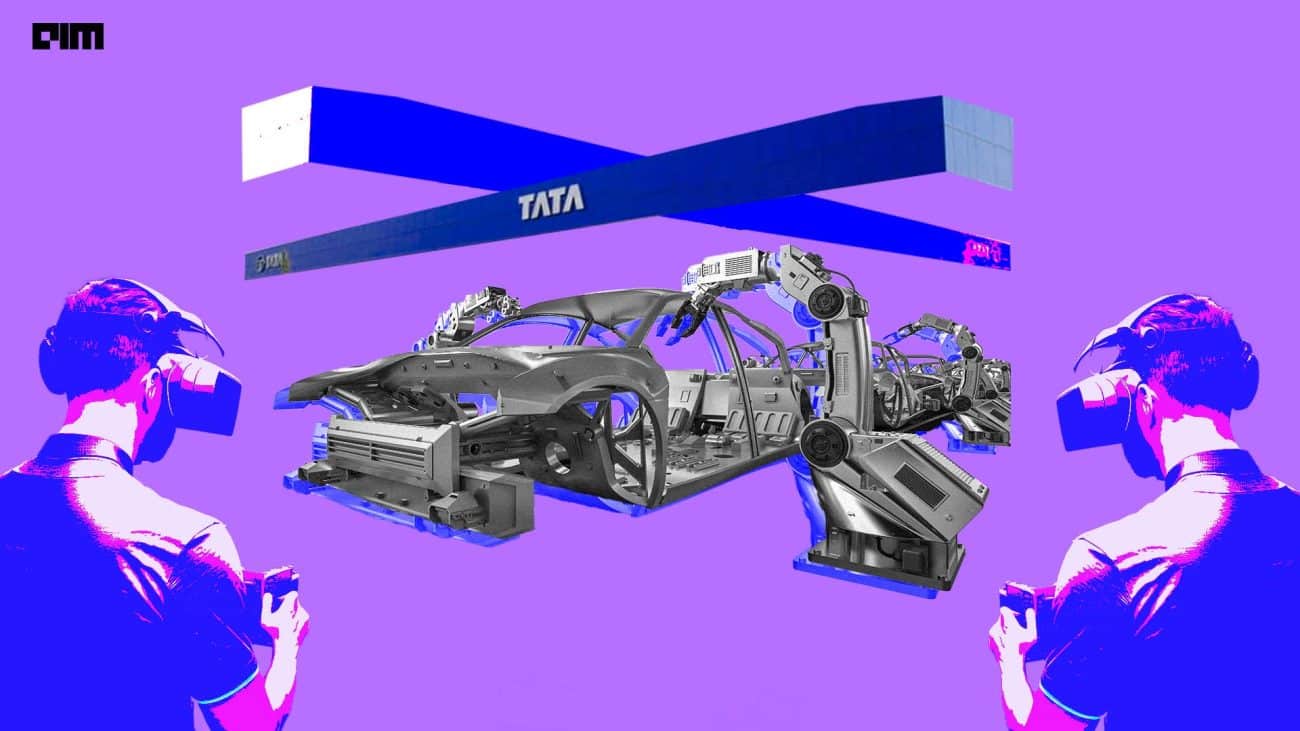

“Since the pandemic, there has been an increased demand for our Cobots,” said Sougandh KM, country manager in India at Universal Robots. In an exclusive interaction with AIM, Sougandh explained that their small Cobot arms can be used in all lines of manufacturing, from assembly to inspection, while also taking up far less space and being safer to use.

Industrial robots used to be large, and take up a lot of space, some were even kept in glass cases for safety purposes. They were a massive investment and used only by large scale manufacturers. Universal Robots are changing all that.

Their portable arm models are built in partnership with 400+ companies that provide the ‘hand’ for tasks not only in manufacturing but also for research and education.

Universal Robots, a Danish company founded in 2005, came about after a research project in the University of South Denmark. The founders envisioned a smaller robot after realising that the market was saturated with large, expensive, and difficult-to-handle ones. Their solution was to introduce a robot arm. Now this arm is advanced enough to manufacture more like them.

Cobot and Safety

Cobot now comes in five different sizes that can lift 3, 5, 12, 16 and 20 kilograms and can be controlled by a small tab that integrates all the functional aspects to it. The arm is versatile as it contains only the head of the arm where multiple ‘hands’ can be connected. Different appendages like pincers, sprayers, suction, camera or any others can be added too.

Universal closely works with companies that manufacture these to sync their hardware and software components. The cost of these Cobots begins at 21 lakh and goes up to 55 lakh.

“For companies like OnRobot or MIR, we have a USB that you have to just plug in to the controller box inside and that’s it. Suppose you don’t have that, then we have a hard wiring cable, which goes around the robot and then plugs into the hand.

Both the arm and the hand are then configured to understand any force applied against it. The settings for them can be changed based on the speed at which a robot moves. “We removed the need for multiple sensors and made it sensitive to any pressure applied on it.”

There are different settings that can be applied to this, from a very small amount of pressure to a physical force that can come in its way which will force the machine to stop. “It is not devoid of sensors, because when it is moving very fast, it picks up the movements beside itself and alerts the arm to stop completely.”

Along with manual safety additions, which can be manipulated, the arm comes with its guardrails which the users can’t override. The arm is designed to be used in dangerous environments that are not ideal for humans to work in. Lifting heavy loads, working with dangerous materials, working on minute wiring, moving pallets, etc. For example in the medical field, they are used in operating rooms to aid surgeons for precise procedures.

They’re now used by the non-profit, Madurai-based organisation Aurolab (a unit of Arvind Eye Care Systems). They increased their Intraocular Lens (IOL) production from 150 to 10,000 lenses per day with Cobots, enabling them to export their lenses to over 130 countries. “India was lagging behind in its adoption of robots in manufacturing, but we receive orders from MSMEs from Tier 3 cities as well,” said Sougandh.

The robot arm is extremely simplified and the software is easy to grasp. The additional tab that comes with the arm contains all the information on the functioning of the arm if it malfunctions. Sougandh said, “We see more women working alongside Cobots.”

Other companies like ABB, Kassow Robots, and Rainbow Robotics all manufacture a similar product. ABB’s GoFa or Go Faster robotic arm has all the features similar to Cobot it is more expensive and bears only a maximum of 12kg load. KUKA’s iiwa robots are bulkier in comparison to Cobot and with a more complex design with a steeper learning curve.

Collaborative robots are small and ideal for manufacturing. “We receive more than 250 requirements per year in India alone,” Sougandh said. By automating repetitive welding tasks, Cobots free up humans to focus on more complex and complex work.